-

Guardian Dye Sublimation Calender / Rotary Heat Press 2" Mandrel

Guardian Dye Sublimation Calender / Rotary Heat Press 2" Mandrel. LIST PRICE: $595.00

$595.00 -

Guardian Dye Sublimation Calender / Rotary Heat Press Work Table

Guardian Dye Sublimation Calender / Rotary Heat Press Work Table for Pieces. LIST PRICE: $6,995.00

$6,995.00 -

Guardian Dye Sublimation Calender / Rotary Heat Press Receptacle for Cut Pieces

Guardian Dye Sublimation Calender / Rotary Heat Press Receptacle for Cut Pieces. LIST PRICE: $895.00

$895.00 -

Guardian 67" Dye Sublimation Calender / Rotary Heat Press

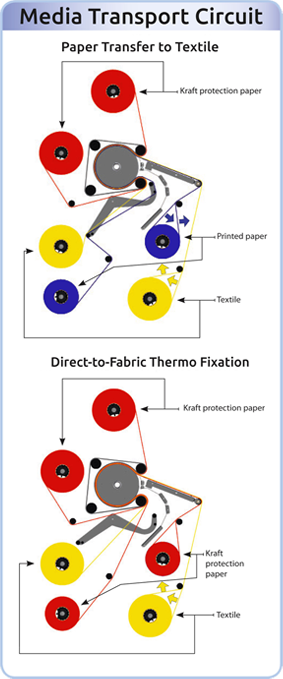

DYE SUBLIMATION CALENDER / ROTARY HEAT PRESS Guardian Calenders are an affordable, easy to use rotary heat press for all your dye sublimation paper transfer and direct-to-fabric applications. The Guardian's intuitive design makes for quick, easy use,...

$29,995.00

Features

- All steel component construction

- Temperature accuracy is controlled by a precision Infra-Red sensor, ensuring consistency heating during the entire transfer process

- Heat is supplied by a specially engineered Infra-Red Quartz Element providing even temperatures when running pieces or roll-to-roll

- Fast warm-up and cool down times save energy and labor

- Nomex felt belt with a Kevlar reinforced center for added durability

- Mechanically adjusted belt without compressed air; the belt does not need adjustment before, during or after the transfer process

Temperature Control

- Temperature is adjustable up to 220°C (428°F)

- Exposure Time: Can be adjusted from 20 to 190 seconds.

Control Panel

- Temperature selection and control. Selection of exposure time and speed.

- Forward, Stop, Reverse Safety reset.

Safety Features

Guardian Calenders include safety features engineered to provide a safe working environment for the operator:

- Plexiglass Front Cover: Protects the user from the feed mechanism and the risk of burns; also protects the felt belt and drive system from being damaged by foreign objects.

- Emergency Stop Buttons: Two (2) emergency stop buttons are located in the front and rear of the calender / rotary heat press.

- System Override: If any of the safety features are activated, the user must press the reset button to reengage the calender / rotary heat press.

- Thermo Isolation: All exposed surfaces have been thermo isolated to protect the user from the risk of burns while operating the calender.

Please feel free to call us at 734-668-0755 or email us at sales@supply55.com for additional information on Guardian Calenders or if you’re interested in becoming an authorized dealer.

| Specifications | |

|---|---|

| Maximum working width | 67’’ (1680 mm) |

| Maximum temperature | 428°F (220°C) |

| Diameter of drum | 10“ (250 mm) |

| Heating system | Infra-Red Quartz Element |

| Heating time from room temperature to 200°C |

30 min. |

| Digital display of temperature | Yes |

| Belt material | Nomex© reinforced by Kevlar for added durability |

| Speed exposure time 40 seconds | 71 yd / hr - 1.18 yd / min, 65 m / hr - 1.08 m / min |

| Speed exposure time 90 seconds | 18 yd / hr - 0.30 yd / min, 17 m / hr - 0.29 m / min |

| Reverse operation | Yes |

| User protection | Safety cover in front of the rollers with safety switches and reset button on the control panel |

| Fume extraction | 2 extraction pipes diameter 2” (50mm) linked to both ends of the machine to vacuum smoke and vapors produced during sublimation |

| Number of self locking mandrels included |

6 universal mandrels, 3 feed, 3 take-up |

| Maximum material roll dimension | Upper position 10” (250 mm), Mid front position 10” (250 mm), Low front position 10” (250 mm) |

| Maximum roll weight | 66 Lbs. (30kg) |

| Power | 5500 W |

| Power adaptor | Plug L6-30P, Receptacle L6-30R |

| Voltage | 208V / 50Hz - 60Hz Single Phase Circuit, Stable Power Required at 214V Output to Calender |

| Amperes | Max. 28 Amperes |

| Dimensions of the machine | W 81” x D 38” x H 61” / W 208 x D 96 x H 155 cm |

| Weight of the machine | 1060 Lbs (480 kg) |

| Dimensions of the shipping crate | W 86” x D 37” x H 66” / W 218 x D 93 x H 170 cm |

| Shipping weight | 1322 Lbs (600 kg) |

| RoHS Compliant / CE Approved | Yes |

| Dye Sublimation Paper Transfer | Requires 100% polyester fabric for dye sublimation paper transfer applications |

| Direct Print to Natural Fiber Fabric | Requires Pigmented or Latex ink for direct printing to natural fiber fabric, after printing the fabric is fixed using the calender |

| Warranty | One year parts warranty 1) Heat elements are a consumable item 2) The belt and drum are not covered by warranty for operator related damage |

Guardian Calender Production Table and Receptacle for Pre-cut Pieces

Benefits of the production table

- The table is removable, allowing for roll-to-roll or piece production.

- Ideal for the production of sportswear and garments using stretchable or non-stretchable fabric.

- Works with tacky or non-tacky paper.

Feeding paper and pre-cut pieces

- Transfer paper can be loaded and tensioned on the front of the table using the transfer paper feed mandrel. (Fig. A).

- The roll feeding guide assists in feeding paper flat into the calender. (Fig. B).

- Printed paper is kept in contact with pre-cut pieces by the pressure bar.

Tensioning of paper

- Paper Tension is adjustable with the tension adjustment knob located on the table paper feed mandrel (Fig. C)

Connecting the table to the calender

- The table is designed to quickly attach and detach to and from the calender / rotary heat press, allowing the operator to seamlessly switch between roll-to-roll and piece production. (Fig. D)

Receptacle for pre-cut pieces

- Easily attaches and detaches to and from the back of the calender / rotary heat press for receiving cut pieces after the sublimation process is complete.

- When not in use, the receptacle can be folded for storage. (Fig. E)

| Part Number | Description | MSRP |

| 55-CL1680DS01-2 | Guardian 67" (1680mm) Dye Sublimation Calender / Rotary Heat Press | $29,995.00 |

| 55-CL1680RE01 | Guardian Calender / Rotary Heat Press Receptacle for Cut Pieces | $895.00 |

| 55-CL1680TB01 | Guardian Calender / Rotary Heat Press Production Table | $6,995.00 |

| 55-CL702107 | Guardian Calender / Rotary Heat Press 2" Mandrel Assembly | $595.00 |