-

KalaXY Dual Mandrel Rewinder

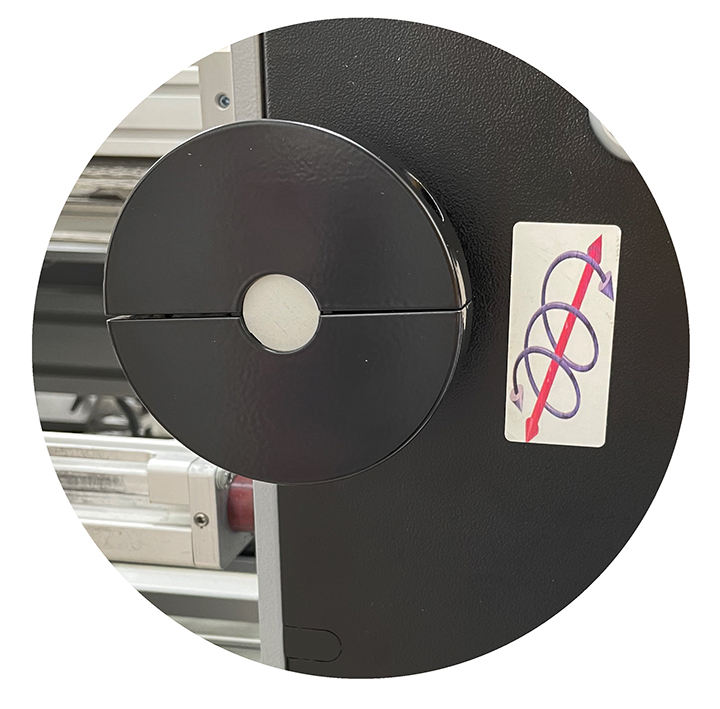

The KalaXY Dual Mandrel Rewinder is a take up system designed specifically for use with all KalaXY Automatic XY Cutters and Trimmers. The device offers an efficient solution for rewinding cut rolls onto either a 3" or 2" core. Designed for taking up...

-

KalaXY PRO 2100 (82") Automatic XY Cutting Machine For Printed, Non-Printed, Direct to Film and DTF Media

Kala XY Pro 2100 (82") is the top of the line model in the product line and includes manual adjsutment of the entire set of Y cutting blades controlled electronically on the fly to correct errors due to misalignment of the printed media. This device also...

-

KalaXY Plus 2100 (82") Automatic XY Cutter for Printed, Non-Printed, DTF and Direct to Film Media

Kala XY Plus 2100 (82") is the midrange model in the product line and includes manual adjsutment of the entire set of Y cutting blades controlled electronically on the fly to correct errors due to misalignment of the printed media. Perfect for printed,...

-

KalaXY PRO 1650 (65") Automatic XY Cutting Machine For Printed, Non-Printed, Direct to Film and DTF Media

KalaXY Pro 1650 (65") is the top of the line model in the product line and is the perfect solution for cutting all flexible media up to 65" in width and 40 mil thick. Print shops rely on KalaXY Automatic XY Cutters to process a wide range of films...

-

KalaXY Plus 1650 (65") Automatic XY Cutter for Printed, Non-Printed, DTF and Direct to Film Media

KalaXY Plus 1650 (65") is the midrange model in the product line designed for trimming all flexible media up to 65" in width and 40 mil thick. It offers several features and specifications to enhance functionality and efficiency when cutting material...

CUTTING METHODS X AND Y

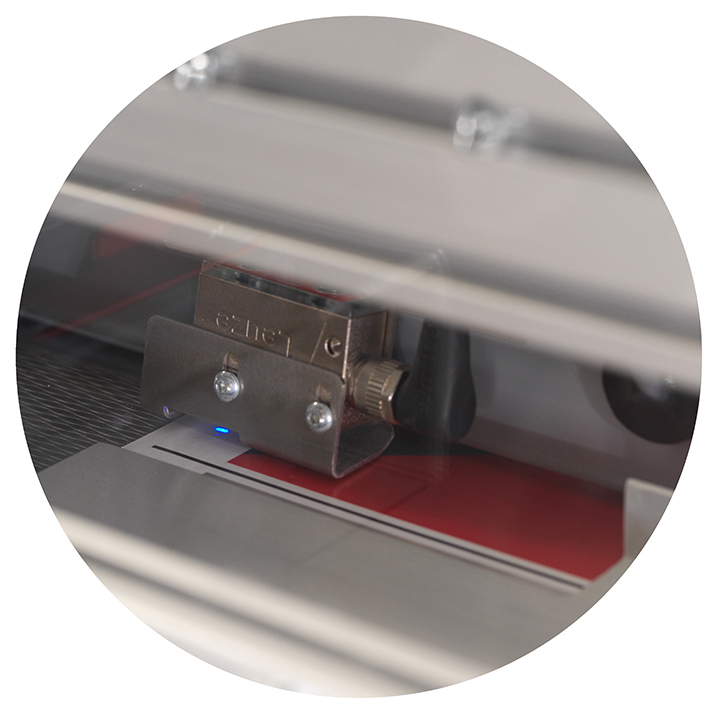

X Cutting - Kala XY trimmer offers several cutting modes, easy to program from its touchscreen control panel. Horizontal or X cutting is done automatically, by reading cutting marks or at fixed programmed lengths. Cutting marks (single or double lines) can be generated with most RIP software available on the market. Exclusive stop mark: the machine will stop automatically upon reading a specific stop mark included in the print file. This mark can be generated in your rip or inserted manually. This allows manual reset the (Y) blade to the required position for the next print series on the same roll.

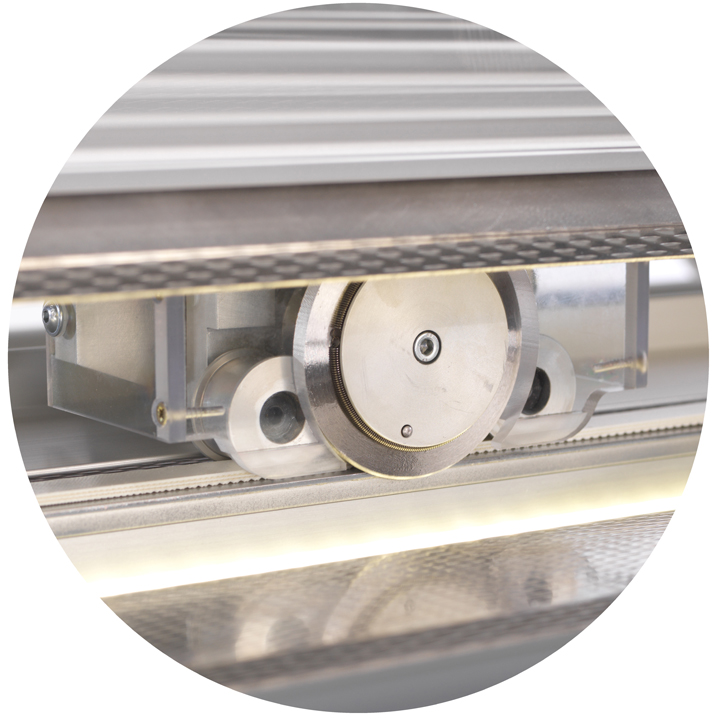

Self sharpening X cutting blade with a counter blade. Two (2) blades are available depending on material needed to be processed. Both blades are easy to change and maintain by the operator to decrease downtime.

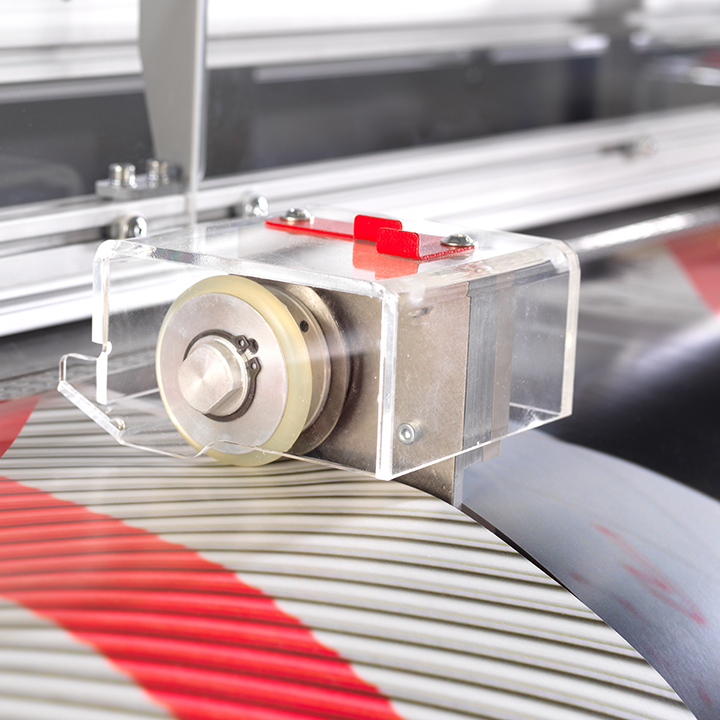

Advanced cut mark detection sensor allowing for the most precise X cuts.

X blade cutting angle adjustment and correction of the X blade to match the exact cutting marks on the print.

The Kala XY Trimmer/Cutter can be operated in 4 different work modes. 3 of the modes allow the trimmer to work with most RIP Software and cut marks. The other working mode is for trimming and cutting set point lengths of material.

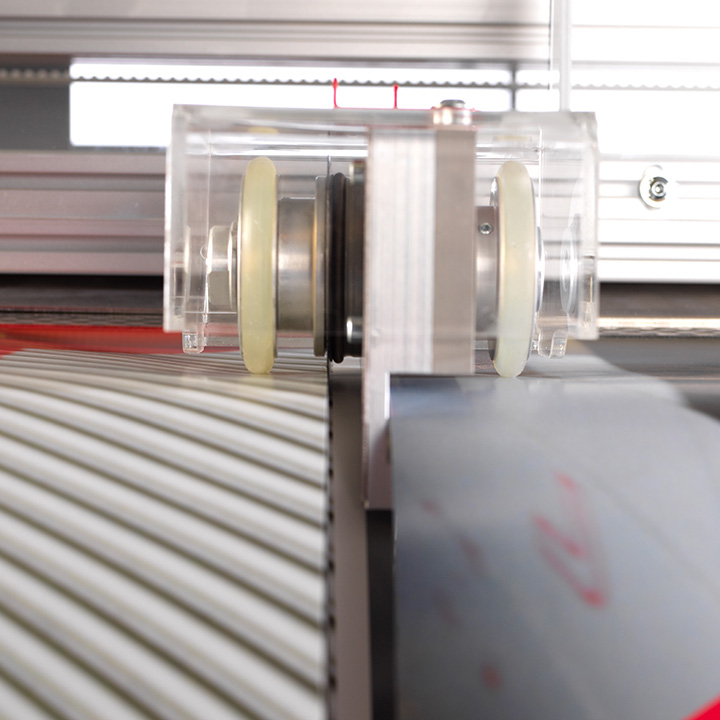

Y Cutting - Vertical or (Y) cutting blades are positioned manually. The machine is delivered with three (3) Y blade holders – two (2) single blade and one (1) double blade. Additional single or double blade holders are available for purchase. Removal media guides to convey the cut sheets out of the machine are included. The Y blades are very easy and quick to change and maintain by the operator.

WORKFLOW CONTROL

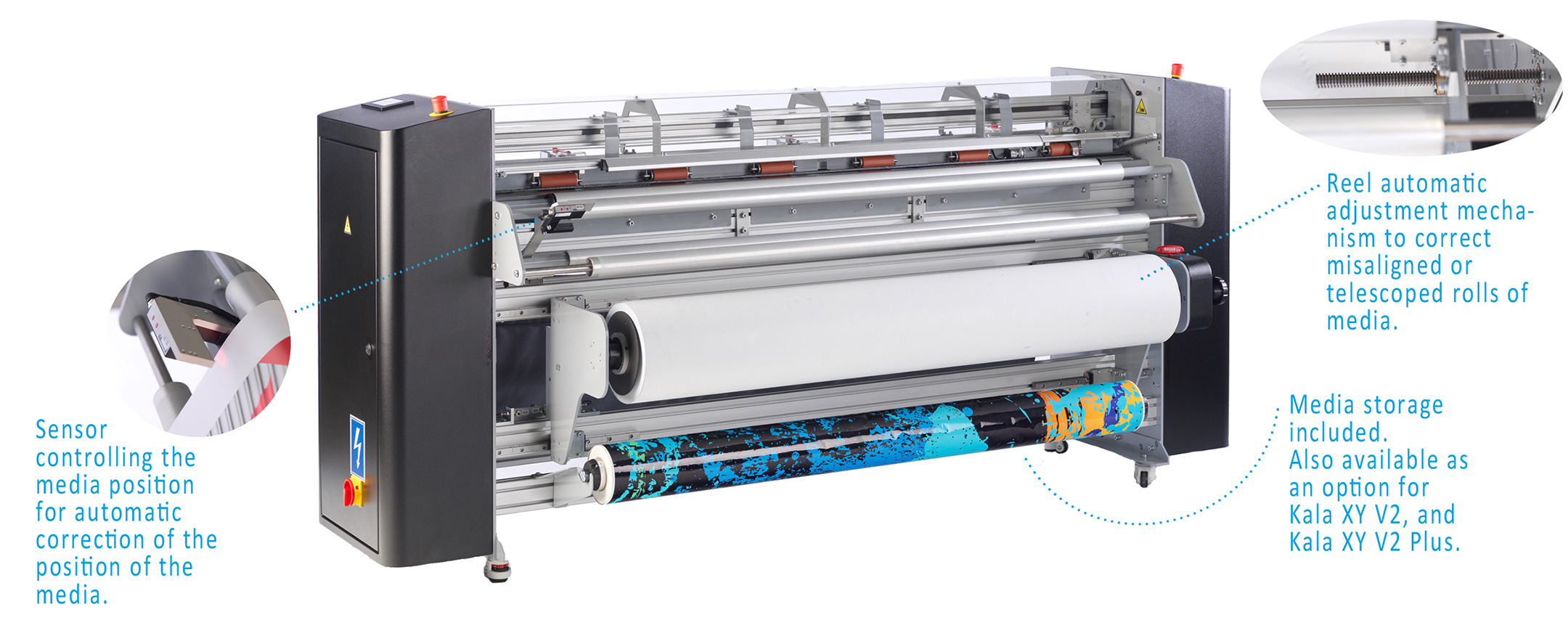

The Kala XY Cutting Machine features a user friendly touchscreen control panel, and automatic media correction via a sensor that detects the edge position of the media and a reel that automatically adjusts the placement of the roll. The Y cutting blades can easily be adjusted on the fly via push buttons to correct errors due to misalignment of the printed rolls.

| Specifications | |

|---|---|

| Max thickness of material | 1 mm - 40 mil |

| Max working width | 1650mm 65" or 2100mm 82" |

| Max media weight | 50kg or 110 lbs. |

| Max media diameter | 250mm or 10" |

| Operating speed | up to 18m or 60 feet per minute |

| Electrical requirements | 110v |

| Accuracy cross cutting | +/- 1mm or .04" |

| Adjustable speed | 1 to 18m/mn or .3 to 60 ft/mn |

| Cutting modes | Mark recognition, set length |

| Electrical adjustments of set of Y blades on the fly | Yes |

| Automatic alignment of media edge | Yes |

| Dimensions | 103" x 33" x 48" |

| Weight PRO machine only Weight PRO w-dual take-up |

334kg or 736 Lbs. 383kg or 845 Lbs |

| Shipping Dimensions | 108" x 40" x 60" |

| Shipping Weight | 450kg or 992 Lbs. |

| Warranty | One (1) Year Parts |

| Certifications | CE and RoHS |

| Software Support for Cutting Marks | SAI, Onyx, Caldera |